PVDF Coating Grade

- group name

- PVDF

- Min Order

- 100 kilogram

- brand name

- Fotech

- Nearest port for product export

- NINGBO, SHANGHAI

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, CIP, FCA, CPT, DDP, DDU, Express Delivery

- Acceptable payment methods

- T/T, L/C, D/P D/A

- Export mode

- Have the independent export and import right

- update time

- Fri, 27 Feb 2026 06:06:37 GMT

Paramtents

CAS No. 24937-79-9

Type Synthetic Resin and Plastics

Purity 99%

Packging & Delivery

-

Min Order100 kilogram

Briefing

Detailed

PVDF Coating Grade FTH-222

1. Characteristic

Properties | Specification | ASTM Test standard |

MFR(g/10min) | 0.5~2.0 | ASTM D1238, 2300C/10kg |

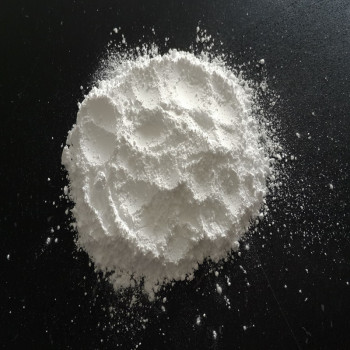

Appearance | White powder | / |

Purity (%) | ≥99.50 | / |

Density(g/cm3) | 1.75~1.77 | ASTM D792, @23/230C |

Scattered fineness(μm) | ≤25 | Hegman fineness gauge |

Water absorption (%) | ≤0.1 | Karl Fisher |

Melting point(0C) | 156~165 | ASTM D3418,100C/min |

Thermal decomposition(0C) | 382-393 | TGA, 1%Wt.Loss, N2 |

Crystallizing heat(0C) | 140 | / |

Surface resistivity(Ohm/square) | ≥1.1014 | ASTM D257/Din 53483 |

Volume resistivity (Ohm.cme) | ≥1.1014 | ASTM D257/Din 53483 |

2. Process safety instructions

(1). This product should be processed under 370℃,to avoid producing toxic gases;

(2). PVDF has good fire resistance and smoke inhibition property, however, when meets with fire, it will release toxic hydrogen fluoride gas and fluorocarbon compounds;

(3). Operators should take good care of personal protection during the use procedure and processing.

3. Packaging and storage

(1). PVDF is sealed in plastic bag with 20kg net weight per bag and then put into drum.

(2). It must be stored in clean, cool, dry place.