Properties and Benefits of PVDF as a Binder in Lithium-Ion Batteries

time2025/07/01

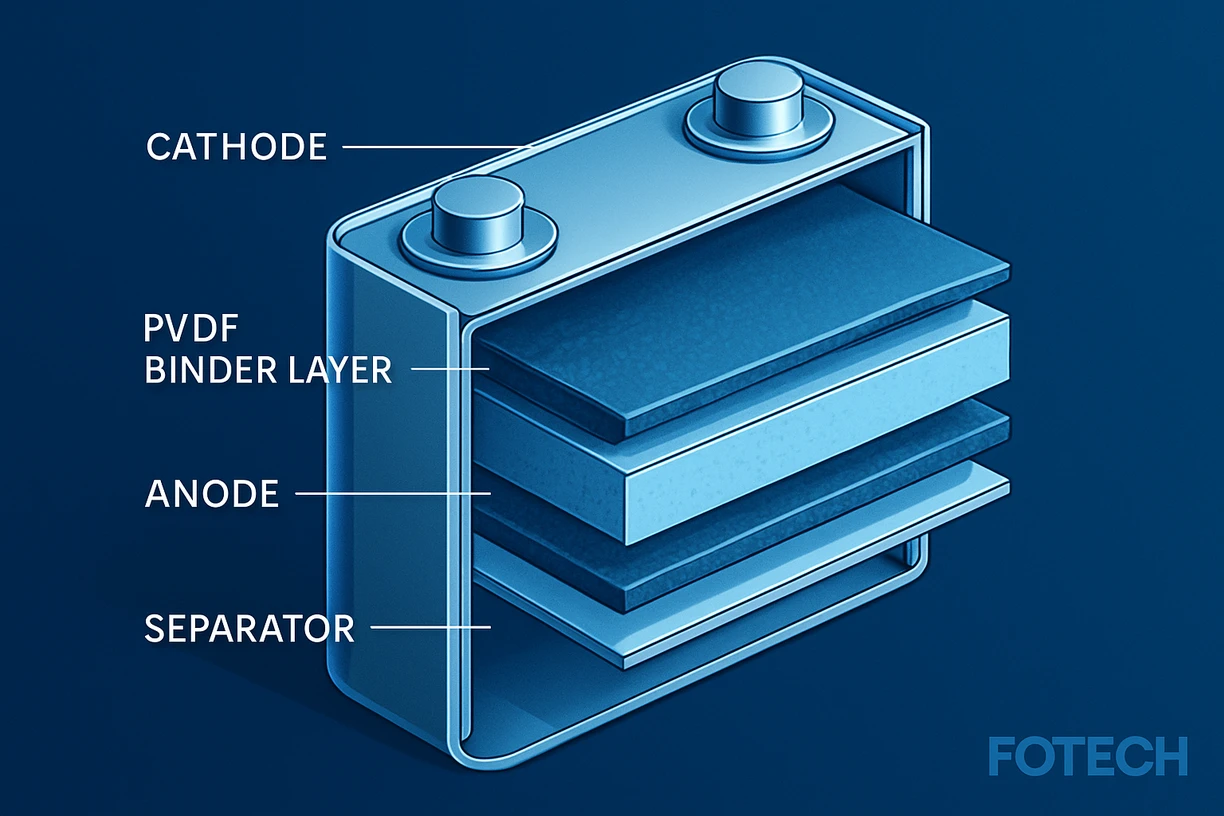

- PVDF is a critical material in lithium-ion battery manufacturing, serving as a binder for cathode and anode electrodes. Its unique properties ensure structural integrity and electrochemical performance, making it essential for applications in electric vehicles (EVs), renewable energy storage, and portable electronics.

Properties and Benefits of PVDF as a Binder in Lithium-Ion Batteries

Discover the key properties and benefits of PVDF as a binder in lithium-ion batteries. Learn how FOTECH’s advanced PVDF solutions enhance battery performance, stability, and longevity for modern energy storage.

Introduction to PVDF in Lithium-Ion Batteries

Polyvinylidene Fluoride (PVDF) is a critical material in lithium-ion battery manufacturing, serving as a binder for cathode and anode electrodes. Its unique properties ensure structural integrity and electrochemical performance, making it essential for applications in electric vehicles (EVs), renewable energy storage, and portable electronics. At FOTECH, we leverage our expertise in industrial automation to provide high-quality PVDF solutions, empowering battery manufacturers to meet modern energy demands. This article explores PVDF’s properties, benefits, and how FOTECH enhances its application.

Key Properties of PVDF as a Battery Binder

Chemical Stability

PVDF’s exceptional chemical stability allows it to withstand the harsh electrochemical environment of lithium-ion batteries. Its resistance to oxidation, acids, and solvents like N-Methyl-2-Pyrrolidone (NMP) ensures electrode integrity during cycling, maintaining consistent performance over thousands of cycles.

Mechanical Strength and Adhesion

PVDF’s high molecular weight and semi-crystalline structure provide robust mechanical strength, securely binding active materials (e.g., LiFePO4 or NMC) to current collectors. Its adhesive properties, driven by van der Waals forces and hydrogen bonding, prevent delamination, ensuring electrode durability.

Electrochemical Stability

With a high dielectric constant and low electrolyte swelling, PVDF supports efficient lithium-ion transport without compromising electrode stability. Its minimal reactivity with electrolytes enhances battery safety and longevity. FOTECH optimizes PVDF for high-voltage applications like NMC811 cathodes.

Benefits of PVDF in Lithium-Ion Battery Performance

Enhanced Battery Cycle Life

PVDF’s ability to maintain electrode integrity during charge-discharge cycles extends battery life. Studies show electrodes with high-crystallinity PVDF achieve up to 82% capacity retention after 500 cycles, compared to 64% for lower-crystallinity binders. FOTECH’s PVDF solutions ensure long-term reliability for EVs and energy storage systems.

Improved Energy Density

PVDF enables higher active material loading, increasing energy density. FOTECH’s automation expertise ensures precise PVDF application, balancing binder content and active material to maximize energy output. This is critical for high-nickel cathodes like NMC811, which demand robust binders.

Support for Advanced Battery Technologies

PVDF’s versatility supports next-generation batteries, such as solid-state and sodium-ion systems. Its compatibility with various cathode materials and ability to form uniform electrode films make it ideal for innovative designs. FOTECH’s R&D drives PVDF solutions for these emerging technologies.

Challenges and FOTECH’s Solutions

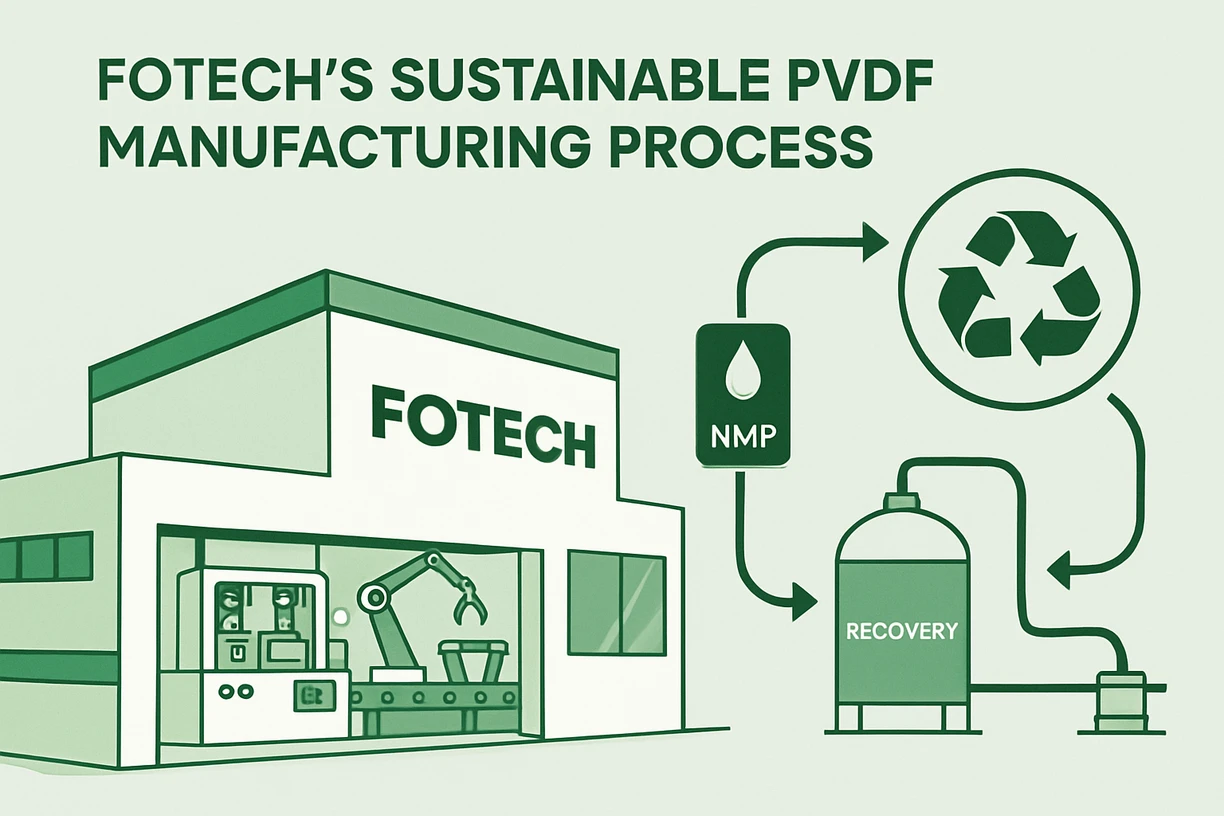

Environmental Concerns with PVDF

PVDF’s non-degradable nature and reliance on NMP raise environmental concerns, including greenhouse gas emissions and recycling challenges. FOTECH addresses this by optimizing PVDF formulations to reduce NMP usage and exploring eco-friendly solvents. Our automated processes ensure efficient NMP recycling, aligning with EU regulations.

Adapting PVDF for High-Capacity Electrodes

High-capacity electrodes, like those with silicon or high-nickel NMC, experience volume expansion, stressing PVDF binders. FOTECH’s modified PVDF with additives like polyethylene glycol (PEG) enhances flexibility, reducing connectivity loss. Our automation ensures uniform binder distribution for stable performance.

Why Choose FOTECH for PVDF-Based Solutions?

FOTECH (..........com) combines industrial automation expertise with material science to deliver tailored PVDF solutions. Our automated systems ensure consistent quality and compliance with industry standards. Benefits include:

- High-Performance PVDF: Optimized for stability and electrochemical performance.

- Sustainable Practices: Reduced environmental impact through efficient solvent recycling.

- Customized Solutions: Tailored binders for specific battery technologies.

Conclusion

PVDF’s chemical stability, mechanical strength, and electrochemical performance make it a vital binder for lithium-ion batteries. Its benefits—extended cycle life, higher energy density, and versatility—drive modern energy storage solutions. FOTECH’s innovative PVDF solutions and automation expertise empower manufacturers to achieve superior performance and sustainability. Visit ..........com to explore our offerings.